Confined spaces are some of the most dangerous and potentially life-threatening work environments in any industry, making ventilation, respiratory, and PPE equipment an integral component of a total safety program. Here are some confined space ventilation safety tips:

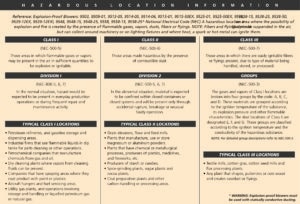

- Proper ventilation procedures should be followed in accordance with all Federal, State, and Local laws. For work in hazardous locations, follow ANSI/API 2015 and 2016 procedures.

- Always test the confined space for hazardous gases and sufficient oxygen with a calibrated multi-gas monitor prior to ventilating the space. After ventilating for a sufficient amount of time, re-test the confined space before entering the space. Ventilation must remain in operation while the confined space is occupied. If the space cannot be properly ventilated, be sure to use explosion-proof products! Allegro offers a wide variety of explosion-proof blowers ideal for instances such as this:

- 8″ Axial Explosion-Proof (EX) Metal Blower

- 8″ Axial Explosion-Proof (EX) Plastic Blower

- 8″ Axial Explosion-Proof (EX) Plastic Blower w/ Compact Canister & Ducting

- 12″ Axial Explosion-Proof (EX) Industrial Plastic Blower

- 12″ Axial Explosion-Proof (EX) Metal Blower

- 12″ Axial Explosion-Proof (EX) Plastic Blower

- 12″ Axial Explosion-Proof (EX) Plastic Blower w/ Canister & Ducting

- 12″ Axial Explosion-Proof (EX) Inline Booster Plastic Blower

- 16″ Axial Explosion-Proof (EX) High-Output Metal Blower

- 16″ Axial Explosion-Proof (EX) Industrial Plastic Blower

- 16″ Axial Explosion-Proof (EX) Metal Blower

- 16″ Axial Explosion-Proof (EX) Plastic Blower w/ Canister & Ducting

- 20″ Axial Explosion-Proof (EX) High-Output Metal Blower

- 20″ Axial Explosion-Proof (EX) Metal Blower

- Centrifugal Heavy Duty Explosion-Proof (EX) Blower

- Centrifugal Standard Blower System with MVP

- Explosion-Proof Extension Cord

- Explosion-Proof Socket

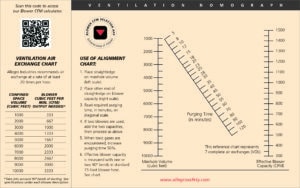

- Use a purge time chart provided on Allegro blowers (see below) to calculate purge times prior to entering a confined space. Each 90º bend in a section of an 8” duct will reduce flow by approximately 15%.

- If toxic/combustible gases or low oxygen levels are encountered, increase ventilation purge times by 50% and re-test the air quality.

- When ventilating a manhole or tank, always set the blower back from the opening a minimum of five (5) feet. This should prevent any hazardous gases that may be purged from the confined space from being drawn back into the intake of the blower and forced back into the confined space.

- Never block or restrict entry and egress to or from a confined space opening. Always use Allegro’s Manhole Ventilation Passthru (MVP) placed in the opening of the manhole or tank to allow continuous ventilation without restricting entry and egress to the opening.

- With gases being heavier than air, the ventilation duct should be placed at the bottom of the confined space allowing the blower’s air to push the gases out the top of the confined space.

- Always use non-sparking tools in and around a hazardous worksite.

- When using a Venturi-style pneumatic blower on a steel tank, make sure the aluminum base is not dragged along the surface of the steel tank; this may cause a spark where rust is forming. Always make certain that the Venturi blower has been properly bonded to the tank prior to ventilating and assure the tank is properly grounded.

- Always have proper respiratory equipment for the ventilated workspace and emergency rescue.

- The build-up of static electricity is more prevalent during cool dry conditions, typically below 50% relative humidity. Depending on the work environment, anti-static clothing and special static removal devices may be necessary to prevent the ignition from static electrical discharge.